My seats and interior package arrived from Classic Aero Designs yesterday. I'll give ya a sneak peak of what it looks like...I just did a quick test fitting for now, more pics later, for now they will be put aside while I finish up the rest of the plane. Keep in mind, the camera didn't capture the true look of the red leather...it looks more subtle and not as bright (...a color in between red and maroon) in reality.

Whats funny to me is that this scheme was a last minute decision. I went through several ideas before settling on this one. The vertical stripe idea was borrowed from Sean Blair. Seeing it, I am so happy I went this route...its so hard to visualize how this will look, it was all just images bouncing around in my head. To finally see it come to fruition...all I can say is, "I crushed that one...home run to deep center!" The arrival of the seats were only rivaled by the arrival of the prop regarding the "size of smile" on my face.

To summarize my feelings, the seats came out awesome and I'm thrilled...they really capture my design intent perfectly. I wanted a high end sports car look...think Ferrari. Mission accomplished...Sean Blair, without any prompting from me (I didn't even mention my 'Ferrari theme' idea) said this when he saw the pics, "Ferrari would be happy to install that any day!" Thanks Sean.

I've yet to see an RV out there with seats that look quite like this, they are bold, that always makes me smile. Life is too short to not walk your own path in life....dare to be different, lead...don't follow.

This was actually the first time I had sat in CAD seats...very comfy!

Ron's RV7 Aircraft Factory

Welcome to my personal blog. This site was created as an informal description of my build progress in the construction of a Van's RV7 aircraft. A place where family/friends/builders/curiosity seekers can follow along. It is not intended to be a detailed description of every step in the building process as that would be much too time consuming. There are plenty of sites that do a great job in that arena, that is not my intention with this site. My intention is for this to be a philisophical/motivational/inspirational account of the emotional ups and downs of the life changing journey...and it will change your life. I hope this will give you an idea, through my eyes, of what its like to make this transformation. A note to other builders, I am not an expert so do not put your safety at risk by attempting anything you see on this site until you have done your own research, or send me an email so we can discuss it. Any deviations from the plans are not approved, nor endorsed by Van's Aircraft or myself. Thanks for visiting.

Tuesday, August 28, 2012

Monday, August 27, 2012

Rocky Mountain Airshow 2012 HOBBS 1484.0 hrs

I had a very busy aviation-filled weekend...unfortunately, most of my time wasn't invested in building...but that's ok, this was time well spent nonetheless. Here in the Denver metro area, we have an annual airshow that has evolved and switched locations several times over the years. It was once called the Rocky Mountain Regional Fly In, and although, you still see that moniker used...I don't think it is an EAA sponsored event any longer?

Now, it usually just goes by the name "Rocky Mountain Airshow" and its held at Rocky Mountain Metropolitan Airport (BJC) where I learned to fly and did my solo flight. Whatever the case, it has been getting better and better the last couple years...and this year was by far the best as they set an attendance record on Saturday. Kirby Chambliss, Melissa and her husband Rex Pemberton, the new "Rocky Mountain Renegades" and the F-22 Raptor flight demonstration were the highlights of the show this year.

The airshow is now a three day/night event. Friday night is the sunset/night airshow and fireworks display. Bob and Shawn Kinney (Bonanza owners) were my wonderful hosts Friday night...kicking off the evening with a hangar party and adult beverages, followed by watching the airshow/fireworks from the ramp. And as you can see from my cheesy iPhone photos...it was a glorious sunset and an enjoyable evening. With the Rocky mountains in the background...it was breath taking.

I was invited to another hangar party at Bob and Mary Markert's wonderful hangar on Saturday morning. This turned out to be another great day being around all things aviation. I could get used to this life. ;)

Bob's hangar is just a few hangars down (and in the same row) as fellow RV7(A) builder Sean Thomas, who shares the hangar with Jim Gray (award winning RV8) and Steve Bergevin (Giles G-202) ...who are both members of the "Rocky Mountain Renegades" RV flight demonstration team. So, of course I ended up hanging out with the team most of the day and late into the evening. Most of them are former military...and you probably know how colorful military pilots are after a few beers....great, great stories! This was their first actual (official) airshow performance and I was quite impressed with their routine as were many in attendance, they did an excellent job. I'm hoping to one day fly with them...first things first however, need to finish my plane! ;)

Bob's hangar party consisted of quite a few of his motorcycle buddies (Bob and Mary both own Harley's)...I also rode my motorcycle, its tucked in there somewhere. It was quite a scene with about 30 bikes parked in front of the hangar.

Here is the only pic I got of the Renegades (although Sean was filming great video all weekend) as they were taxiing out for their Sunday performance. I didn't carry a camera all weekend...so you're stuck with iPhone quality pics. :)

Saturday was an all day affair, as we ended up going to a VIP party for the airshow performers later that night...where I met Melissa and Rex Pemberton (sorry no pics) and was rubbing elbows with the F-22 team. Melissa was very friendly and personable, mature beyond her 28 yrs, a great ambassador for aviation...I enjoyed talking aerobatics with her. Oh, and she's pretty cute too. :)

I had so much fun Saturday, I came back out on Sunday and spent the day again. My instructor, Dagmar flew the Pitts into the field and I introduced her to Melissa--who had requested an introduction Saturday night...as they are both going to be competing next month in the National aerobatic championships in Texas and had never met. It was cool to see two generations of women pilots talking about flying...and oh yeah, Kirby (quite a funny guy) was also hanging around chatting with us....ho hum. I was in awe, pinch me, this is aerobatic royalty for gosh sakes!

What a weekend! Special thanks to all my wonderful friends for their warm hospitality, I am fortunate they let me hang around...Bob and Shawn, Bob and Mary, Jim and Lindsy Gray, Sean and Dianna. Great, great people...one and all.

Friday, August 24, 2012

Aveo Switches HOBBS 1476.5 hrs

I received my Aveo switches...I already had some of the covers and the mount housings, the last part of the puzzle were the switches themselves. I snapped them together...and was very pleased with them...nice, robust switching action. Here you can see, I am trying to do a layout of sorts...I only have ten spaces in the panel so I need to use them wisely. I also want to consider cockpit "flow" with their locations. The ones at the top are the "leftover" ones that don't fit in the ten spaces...I may add some or all of them somewhere else on the panel.

Lighting...these are pretty standard, I don't think there is anything to think about here. The wig-wag function will be controlled by the VP-X unit so I don't think I need a switch for that.

Here is where I am doing my head scratching (notice these switches aren't snapped into their housing just yet)...the battery master, left/right mag and avionics master are also pretty much standard. But what else? Boost pump...starter...maybe. Although, if I go this route, this starter switch will only make my stick starter switch active...i.e., switch Aveo starter button on...then push stick starter to actually activate the starter. That way I don't have a kid (or me) accidentally hit the stick starter by mistake...it takes two deliberate actions. I will not have a key. Still debating this setup however...

Coming together nicely...ignore my "mad scientist" mess of a workbench!! :) When I get to working...I make quite a mess!

Bought a 2" hole saw and drilled holes for the SteinAir fresh air vents. As you can see, they fit perfectly.

Lighting HOBBS 1476.5 hrs

Except for my landing and taxi light, I am going exclusively with LED lighting. They use less power and should last forever. To me, this is a no brainer as I think all lighting will go this way in the near future. My manufacturer of choice is Aveo...I like their products.

I had originally planned to go with the cheaper "Powerburst" but they are not recommended for anything beyond LSA's and ultralights, certainly not for IFR. So I bought the "Ultra Aurora" instead, which is of course a little more pricy. These are 3-in-1 lights...nav/position/strobe. They look indestructible...and it must be the geek in me, but I think they are really nice looking.

Tail/rudder strobe

I started mounting the tail strobe, still got some work to do...I filled the fiberglass cap with some flox and then just drilled and tapped into that. I plan to make my rudder bottom permanently attached, so I need to plan accordingly.

Balance of Avionics HOBBS 1476.5 hrs

Last Friday I received the balance of my avionics from Stein. This was the stuff that I used Oshkosh to make my decisions. The Garmin GDU-375 (ultimately becoming a G3X one day), Garmin GDL-39 for ADS-B traffic and weather, Garmin SL-40 Comm, PS Engineering PAR100EX Comm/Intercomm/Audio Panel and lastly, a GPS antenna for the GDL-39. This finishes off my avionics procurement...essentially a deluxe VFR platform that can easily be transitioned to IFR later.

So, of course, you can guess what I was doing last weekend...playing with shiny new avionics! Or I should say mounting them in my panel. I haven't fired anything up yet.

The box of goodies from SteinAir...

Stein is great about throwing in a t-shirt and key chain, complimentary. You might say, well, you just spend thousands of dollars with them...isn't that the least they can do? And yes, that's true...but do you know how many free t-shirts I have received from other vendors?? Only Aerosport power...you would think Van's would give you something don't you? Anyway, its a nice gesture and appreciated. SteinAir's customer service is second to none and I'm a fan.

Also notice the blue zip ties...these are special high temp tfezel versions for the FWF. Kinda pricy, but I know how regular zip ties can get brittle in a high temp environment.

This was a tough decision for ADS-B...Garmin or Dynon? I went with Garmin as you can see...I like this unit because I can hardwire it directly to my GDU-375 and it will also blue tooth to my iPad at the same time. Plus its $200 cheaper than Dynon's version...which isn't available just yet.

My PS Engineering PAR100EX...bottom box is the actual remote mounted Comm, made by MicroAir I believe?

GDU-375 box....

SL-40 Comm, this will be my primary Comm. I debated over Garmin and Icom...you can see who won. I just heard too many hokey things about the Icom. The Garmin is more expensive, but I wanted a good solid comm and I think this fits the bill. I'm not saying the Icom is a bad comm...but I think the Garmin is more robust...at a cost.

The cheap ($30) GPS antenna for the GDL-39...still not sure where I am going to mount this bugger?

Remote mounted Comm...I may mount this behind my baggage bulkhead...debating...

How they look stacked together.

Some final layout work...actually sitting in the cockpit seat...the Dynon is directly centered in my line of sight.

Lets cut some holes!

The corners of the Dynon are pretty square, but I wanted some radii on my corners to eliminate stress concentrations. This is one way to do it...be careful though, the Dynon bezel does not overlap very much top and bottom. You don't want your hole showing.

Skyview mounted...now for the Garmin...the mounting plate supplied by Garmin makes a good template for your hole.

And voila! We have and EFIS and a MFD mounted. I was surprised at how heavy this thing was getting once I mounted those two bad boys. Looking good though.

Moving on to the radio stack...this will be a little more difficult...and I am still in the middle of this process. More pics to come.

Over the weekend, I stopped by another builders (Lyn) project after the EAA Chap 301 bbq and was poking my head around his FWF work. I noticed that he safety wired his oil filler...and then realized, when Dad and I put it on...we didn't do that. So, I remedied this. Things like this are easy to miss if you've never done this before.

Wednesday, August 22, 2012

ANL Current Limiter HOBBS 1476.5 hrs

I spent some time installing my shunt and ANL current limiter on the firewall. Another one of those tasks that is pretty straightforward, but seemed to eat up a lot of time. Adding a doubler to the backside of the firewall was part of the time consuming part.

When you get to the FWF stuff, you are very much on your own. The learning curve has been steep for me. Since all FWF installs are slightly different, Van's doesn't give you much documentation to go on. You will have to mix and match for your particular setup. Thankfully, today, there are many good builder websites to look at that have similar or identical systems to yours.

I am following Bob Nuckolls Aeroelectric Connection as my guide for all things electrical. His book is far and away the best reference I have found out there for homebuilt aircraft electrical systems.

First things first, what the heck is an ANL current limiter...at least that was my initial question? Bob recommends this, and since he knows much more than I do about such things, I am putting my faith in him. Basically, "it is a device that behaves like a fuse with much longer time constraints" (Knuckles). It is used for protection of the alternator B-lead. Here are some pics of my install...

You can buy your ANL current limiter, base and optional cover from B&C. This cover, only about $7 is a nice addition to protect the device...it gives it a nice professional look too. You can see, this current limiter is a 60A version, to match my 60A alternator. Be sure to choose the correct one for your install.

I mounted my shunt (from Dynon) directly underneath it, connected by a copper bar. Notice the small cuts in the shunt bar element. I emailed Dynon about those, since I didn't see those on other installs and was curious why mine had them? They said they have switched to a new supplier and that's how they calibrate the shunt.

Here is a shot of the full install...showing the connection to the master and starter solenoids...again, with shrink tubed copper bar. Notice, mine is moved over to the left to have easy access around the engine mount. Always keep ease of future maintenance in the back of your mind when doing your FWF layout.

The install, like I said, was pretty straightforward, but it took me a couple hours nonetheless. And a parting shot of my bloody hand (really just small cuts...looks worse than it is)...watch out for the sharp SS firewall when you drill holes in it, gosh I hate drilling the firewall. Just another reason to LOVE working with aluminum. Hey, you cant build one of these puppies without shedding some blood, sweat and tears!! Check!

Wednesday, August 15, 2012

Van's SB: Wing Bolts HOBBS 1457.0 hrs

SERVICE BULLETIN SB 12-08-14

New service bulletin by Van's...make sure you dont forget these bolts when you install your wings.

New service bulletin by Van's...make sure you dont forget these bolts when you install your wings.

Slow Rolls & Hammerheads HOBBS 1457.0 hrs

Lesson #4 in the Pitts was all about slow rolls, Immelmans and Hammerheads. We started out doing some more dutch rolls like we did in lesson one. Its always good coordination practice with aileron and rudder. Rudder as you roll into the bank to offset the induced drag...and then switching back to the other side, quickly, and doing the same the other way.

The reason for this, other than the practice was Dagmar wanted me to do these inverted during this lesson. This was preparation for doing slow rolls. Slow rolls are a competition maneuver and the name is somewhat confusing. They can be done at any roll rate...not necessarily slow. The key to these is, unlike aileron rolls which start with a pitch up before rolling, these are done with the nose stationary on the horizon...no pitch up. So, as you roll to knife edge...top rudder, continuing to inverted, forward stick...around to knife edge, and again top rudder...and finishing upright with probably a little aft elevator depending on your airspeed. The goal is to do the entire roll with no loss or gain of altitude...always looking for straight lines in aerobatics.

I describe this process as being mechanical, but to do it smoothly you are gradually feeding these controls in and out during the roll..its far from mechanical, its a "feel" manuever. Its very much a control coordination exercise and let me tell you its plenty difficult the first few times. But gosh, what a great stick and rudder exercise...if all pilots could master this, we assuredly would be better stick and rudder pilots.

Now that you know what a slow roll is, lets talk about my experience trying this. Dagmar says, check your seatbelts (should always do this before doing negative G maneuvers), I check and reply, "good to go!" Inverted dutch rolls here we come...roll inverted, then proceed to roll left and back right...ah, but the difference...and difficulty is its left aileron coupled with right rudder. Yes, it sounds cross controlled, but its not. And its difficult to get past the mind trying to do what it thinks is "correct"...it takes plenty of concentration...my head hurt. Of course, I botch it pretty badly and we end up all over the place. The nose swinging wildly with my clumsy rudder inputs.

Next we do knife edge flight...roll 90 degs to our side. Short durations since the oil system doesn't like knife edge flight...upright or inverted it can handle just fine, knife edge, it is not set up for. This was an exercise in learning to use "top rudder." When in knife edge flight, the rudder becomes your elevator...and since we are now using the inefficient fuselage as our "wing"...it takes quite a bit of top rudder to hold altitude.

Now lets combine these and try a slow roll. Wowza, my first attempts were plenty ugly...I was rolling too fast...trying to cheat my way around. Dagmar says, "slow down until you get the hang of it...we can do them faster later." I was losing altitude like a gambler hemorrhages chips playing craps on a bad night in Vegas! I struggle with the control inputs as we roll, I'm constantly behind the airplane...get back to upright, and Dagmar says..."ok, you lost 1000' on that one." Ouch, are you kidding me?!! Its not easy boys and girls. At least I can only get better I think. We do several, and I did improve, but Dagmar says its a maneuver that usually takes a couple sessions to grasp...I shall sleep on it and try again.

Next up is the Immelman...a half loop followed by a slow half roll to upright at the top...again, without losing altitude. Its an energy management maneuver, as you get to the top, you are slow and low on energy...near stall speed. We need to roll...efficiently, so as to not rob that critical energy from the airplane since we don't have any to spare. All the while, not stalling and entering a spin. I've done a few of these already and not had too much trouble. But now, actually trying to do it correctly...i.e., hold altitude...it was much harder. I did several...they were sloppy, but mostly I did ok on these.

Now for the best part of this lesson. Dagmar says, "lets try some hammerheads". Giddy up! I've been itching to do these since we started this adventure. I've always been fascinated with this maneuver since I was a small boy and couldn't wait to see what they were like from the cockpit. You may remember, I had done a hammerhead entry...followed by a torque roll and inverted spin...in a previous lesson. Now we were going to do them correctly.

Again, pull 4G's into a vertical upline...hold it, as our airspeed decays...feed in some aileron and rudder to counteract the left turning/rolling tendency. There is a slight shudder as all forward motion almost stops, then its this, mechanical, control sequence: full left rudder, full right aileron, slight forward elevator...as we pivot, right rudder to stop the nose on our downline...then neutralize all controls, pick out a point on the ground and straight down we go...screaming back toward the earth! Woohoo! Hold the downline, now pull out with another 4G pull. Dagmar says in my headset..."good job, now go right into another one"...well shoot, alright, why not...this is a kick. I had read enough about this maneuver beforehand and really nailed these right from the get go. That made me smile...finally felt like an aviator again, as everything else had been pretty humbling up to that point. They are actually pretty easy...and boy, a ton of fun...I could do these all day!

After quite a few successful ones, Dagmar again wants me to intentionally botch one...see a pattern here? She says...do one, but instead of pivoting...just hold the vertical upline and lets see what happens. I had done this before with her, so I knew what to expect. We slow...the aileron finally loses all effectiveness and we start torque rolling to the left...followed by a tailslide when we run out of energy. Of course, this induces a spin...ah, but that's the goal with this! haha!

Again, it worked perfectly...another lesson learned...let me explain. I did remember to cut the power like I learned previously...that was good. Ah, but this time I hauled back on the stick too hard and too soon...entering a secondary stall. I continued to do this until Dagmar chirps, "get the nose down, you're stalled!" Duh I think...why didn't that register in my brain until she said it? Again, panic...its a common reaction to pull back on the stick. Pay attention to what the airplane is telling you, because it was talking and I wasn't listening...get past the "brain lockdown" mode and actually THINK. Its not easy to override your survival instincts. Does this scenario sound like a common accident? We see it all the time. So, this was my takeaway from this lesson. I try to have at least one thing from each lesson.

The other takeaway was this. As we got into doing botched Hammerheads, Dagmar says..."if you miss your pivot and find yourself at the top with no airspeed and a pending spin coming, cut the power. It will remove the energy out of the system." Think about it, you are at zero airspeed, pointing straight up, with a 260hp engine screaming at full tilt. All kinds of things going on...torque, spiral slipstream, gyroscopic precession...with no control authority to counteract it since we have no forward airspeed. Chop that power and the airplane gets more manageable immediately. Worked like a charm as the Pitts turned from a rabid pit bull clawing for altitude to a purring kitten in the flash of a second.

The unintentional spins are great learning experiences, I like the fact that Dagmar forces me into them. If you are the "perfect" pilot right from the get go...flying every maneuver perfectly, how will you ever know how to recover when you finally screw up. Better to learn this now with Dagmar, than later solo.

This lesson was by far the most G's I had pulled in one session. The Immelmans and Hammerheads (we did quite a few) all require that 4G entry. It wears you out...I was physically drained at the end of this lesson. Still having a blast...until next time.

Tuesday, August 14, 2012

Cowl & Panel Work HOBBS 1457.0 hrs

There has been a lot of progress lately in the Factory...I will warn you that every detail of the FWF will not be posted. As I've transitioned to FWF work, I've been doing a lot of reading/education and I've also been relying heavily on Jason Beaver's great site for guidance. His build is very similar to mine and his site is more detail oriented. I just don't have the time...I'd rather build. He's got some good ideas that I am borrowing. I recommend you check it out.

He, like me, are the last of the "Checkoway disciples"...a lot of the inspiration for my site came from my chats with Dan Checkoway before I started and I know Jason actually knows him personally. His site reflects the Checkoway lineage as well....very well done. Its interesting to me that new builders aren't even aware of who Dan Checkoway is, but if you were building 4 or 5 years ago...his was the 'de facto' build site...he set the standard.

Ok, enough about that...as I said, I've been very busy...lots of things coming together lately, this stage of the build is very exciting. I am hyper-motivated right now.

Cutting my panel inserts, drilling the mounting holes...installing nut plates, etc.

My CAD side panels showed up for fitting. With the JDAir latch that I installed, CAD likes the owner to do his own fitting...cut out around the latch. So they send just the thermoformed plastic with approximate areas for trimming. You cut it to fit and then send it back for covering. Its a little aggravating to spend $45 on shipping to send it back...I think they should cover costs for this, but its not going to keep me up at night.

There were no instructions, so first order of business was how to cut this stuff? Its pretty thin and lightweight, I first tried heavy duty scissors without much luck. Then I said how about my snips? Worked pretty good...tight inside corners were tough but I just did a rough trim with these. Anytime you are cutting something where its crucial not to cut too much (you cant put it back on)...trim a little at a time, as I say...sneak up on it.

Fine trimming was done with my dremel tool...worked perfectly.

No trimming around the Aerosport panel needed...the side panel tucks perfectly behind it.

Starting to look like a finished airplane eh? Well, maybe not quite yet...but its taking shape!

Be aware, you have to do a fair amount of "surgery" on the panel to get it to fit with the side rails and canopy frame. Here is the start...more to come later.

With the SJ cowl, you will need to cut your oil door. I used the circle (shows where the dip stick intersects the cowl) as my target and settled on a 6.5" x 6.5" door. I then cut it out with a jigsaw so I could use the cut out piece as my door. Came out real nice...I have more work to do on this, but this is a good start.

Plenty of builders complain about the cowl fitting...I gotta say I am really enjoying it. The SJ cowl fits real nice and the fiberglass work is far superior to the Van's cowl. I'm very pleased I went this route (talk to me later if I have cooling problems). The fitting does take some time--not done yet, but it is kind of fun to me.

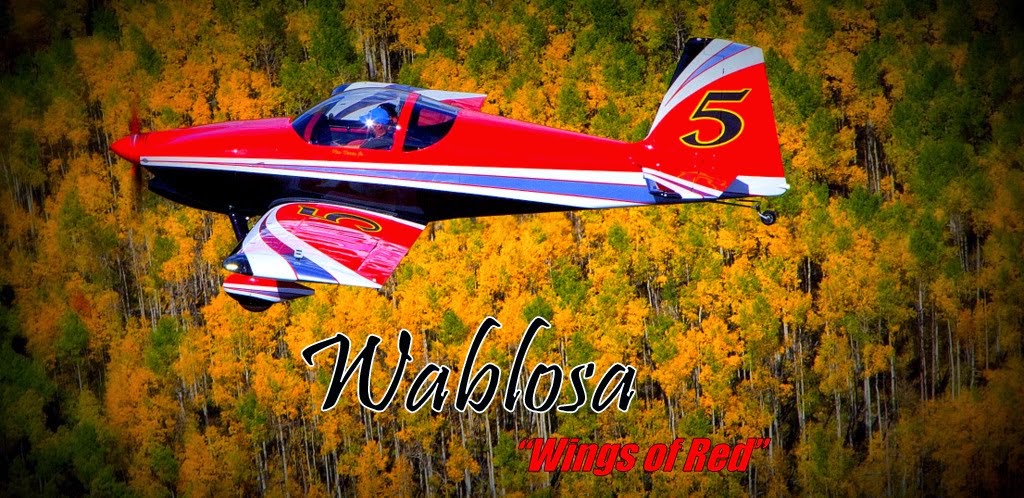

Of course, pics like this help make it fun...with the canopy down and the cowl in place, Wablosa is looking very sleek...sexy even.

Drilling the upper cowl hinge...

Side hinges...I debated how to do my side cowl pins...remove them through the cockpit via a hole in the firewall or do a nice cowl pin cover? I chose the latter...Aerosport Products does a nice set of these...I will either buy theirs or build my own.

Attaching the hinges...standard rivets coupled with "flox rivets". The 1/4" dia holes will get a dab of flox to help with the standard rivets vibrating loose over time.

Flox applied...this bugger isn't going anywhere.

Notice the added piece of alum I used to cover this air gap between the upper cowl hinge and the bottom cowl. Certainly don't need it but I also don't want a gap where I can see into the engine compartment....just a cosmetic thing.

Match drilling the side hinges to the cowl. I did the side hinges last...the last amount of fine tuning can be done leading up to this step, once you lock down the sides it isn't going anywhere. So...tweak it (fine tune it) to exactly where you want it and nail it down with side hinges. I left a 0.040" gap between the two cowl halves for paint...dont forget to allow for paint thickness.

Notice the rivets across the top...I just used my rivet squeezer on these, worked perfectly...don't try to use your rivet gun...not sure why you would though? I will cover these with filler and you'll never know they are there.

I wanted to install my EGT sensors in the exhaust, first though, I thought I would put the lower spark plugs in to make sure I wasn't interfering with them for maintenance. Don't forget your spacers if using auto plugs like me...anti-seize added to the threads.

Dynon EGT thermocouple...this just inserts into a 1/8" hole drilled into the exhaust and strapped down...choose a location 2"-8" from the flange...whatever you choose, be consistent on all four. I went with 2".

I thought about angling them toward the rear but was worried they may get in the way of the spark plug wires and cause maintenance issues. I knew there was clearance around the cowl so I just stuck them straight out. The cable ties are temporary...I will replace them with high temp versions later. I also safety wired the hose clamps...not a safety of flight issue if these came loose but it could cause a CO problem from an exhaust leak. Also, you dont want these buggers coming loose and flopping around your engine compartment in flight. I say, if in doubt, just safety wire it...you'll sleep better.

Not sure I ever posted this...I was confused where to put my oil temp sensor. I asked the guys at Aerosport Power while I was at OSH...with the 90 deg oil adapter, where does that puppy go? Here you can see where it goes, which is different than the standard filter housing...its the brass fitting under the filter.

Subscribe to:

Posts (Atom)