As I settle into my flight testing now that the first three flights have been completed, I thought I would give you some of the details of what lies ahead. Since my prop and engine combination are not STC approved (a certified combination), I am forced to do 40 hrs of test flight (vs. 25 hrs otherwise). In that 40 flight hrs, I must demonstrate (i.e, test) the operating limitations that I plan to operate the aircraft under. For example, if I say it is spin approved...I have to prove that by doing spins; rolls...same deal...loops, etc. This also applies to limits in my POH: weight, fuel, g-load, Vne and so on. I will need to test all of these configurations to ensure safe flight.

Beyond that, there isn't much detail to what you absolutely HAVE to do during your 40 hrs. They expect the basics to be done: Vso, Vs1, Vx, Vy, etc. I know plenty of pilots that mostly just fly around in circles for 40 hrs. That's definitely your call. For me, I want to actually "test" the safety of the airplane in all flight phases before I allow a passenger to ride in it. I will be using Mike "Kahuna" Stewart's flight test cards, which are available off the internet. I have modified them to suit my needs and personalize them in general.

In addition to flight testing, this is your time to bond with your new airplane...get to know each other intimately. What better way to do that than to explore the flight envelope. I am already feeling more comfortable with her after every flight. By the time the 40 hrs is complete, I will have vastly more confidence in the airplane and what it can do. That's a big deal and a worthwhile goal.

This is the test area designated by my DAR. You can request an area in your application, my request was essentially all of eastern Colorado. With an airplane that cruises at 200+ MPH, a large area is very desirable. I'm not flight testing a piper cub for goodness sakes. My request was essentially ignored by my DAR, which was pretty aggravating...although at that point I wasn't going to argue as he has your future flight status solely in his hands.

If you click on the map above, you will see a pretty close representation of where I can fly during my 40 hrs. The furthest point of the triangle is Sterling, CO...about 95 nm from my home airport in a straight line. At RV speeds, that's about 35 minutes away. I now have 7 flights completed...and this area is getting pretty boring pretty fast. The good news is its wide open, desolate country, with not much of anything going on...plenty of dirt roads and open fields to set her down if something goes wrong.

Even with my gripes about the small area and ugliness of the terrain...I still, amazingly enough, get excited to fly to Sterling! That's what RV flying does to you...it really doesn't matter what you are flying over as long as you are flying your creation. It is quite addictive...this RV-ating.

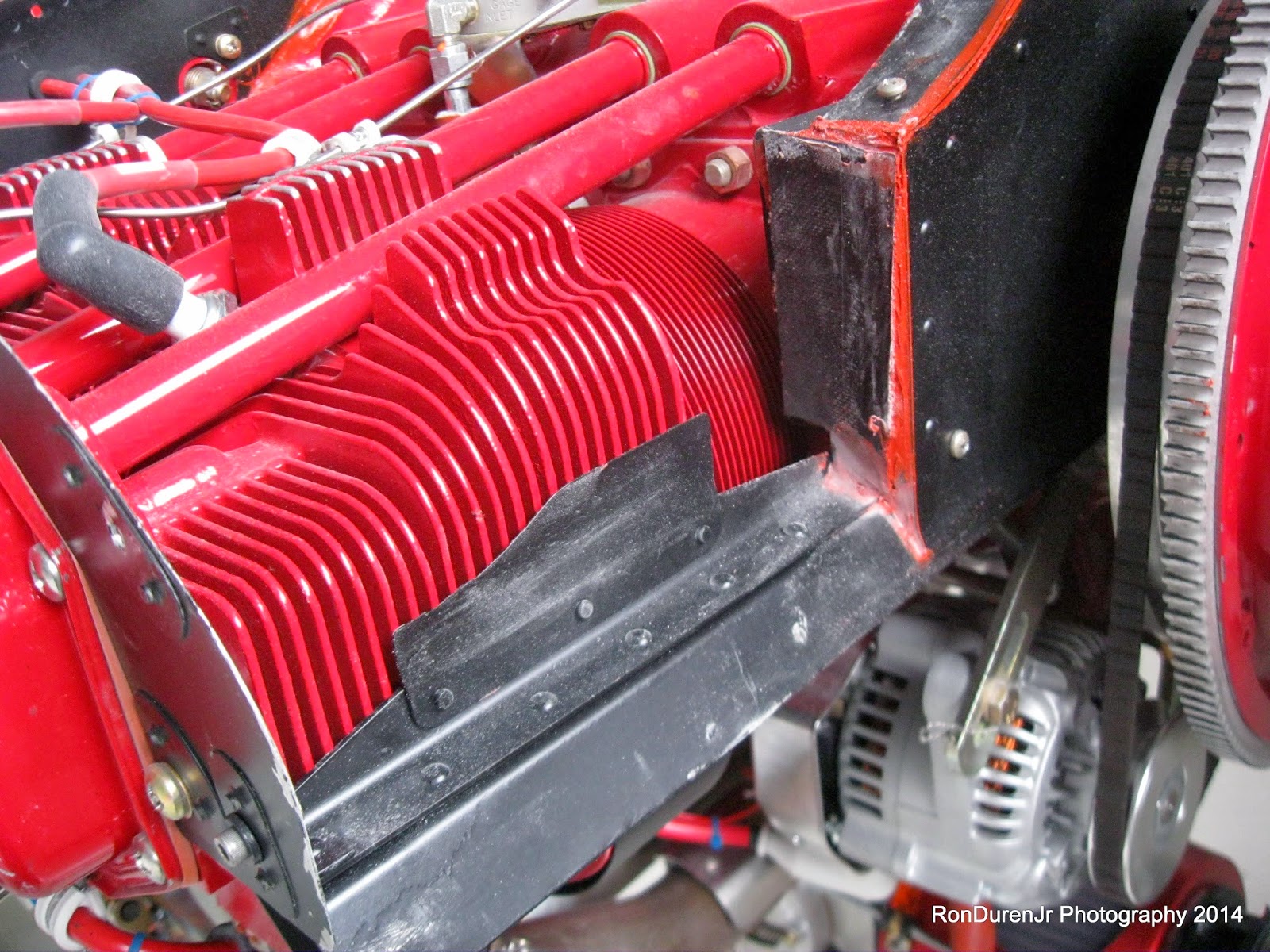

These screenshots show the objectives of the first three test cards (the details are omitted for brevity)...which have all been completed. I will publish these (28 of them) as I progress so you can follow along. After the third test card, the fourth flight card is slow flight testing. I decided to work on getting the engine broke-in before doing that one. After seven flights, I now have 10.5 hrs tach time on the engine and it hasn't shown any indication it is broke-in yet (i.e., CHT's coming down, oil consumption coming down, etc). CHT's are running about 375-425 deg F, although I haven't done any sealing of gaps yet on my plenum. Oil consumption is about a half quart per hour right now.

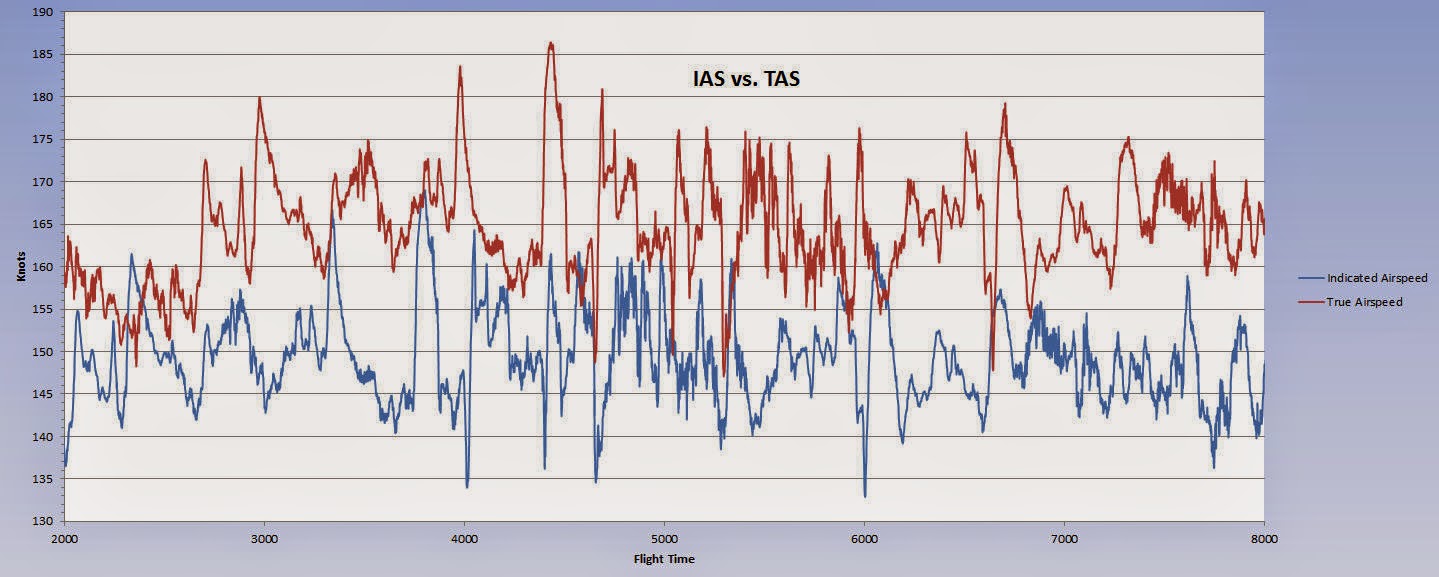

I called my engine manufacturer Aerosport Power and asked them, should I be worried? They said, nope...this isn't unusual. I was instructed to keep running her hard as I have been (70-75% power) and if nothing happens in the next ten hours to call them back and we'll talk again. I may mix in some other test stuff while I do it, like GPS airspeed indicator testing. They also said, try to do longer flights if possible...not 45 min or 1 hr. I've been doing essentially 2 hr flights the last three, so I am good in that regard. Hopefully soon she'll break-in and I can breathe a sigh of relief...and get on with other flight testing.