Ron's RV7 Aircraft Factory

Welcome to my personal blog. This site was created as an informal description of my build progress in the construction of a Van's RV7 aircraft. A place where family/friends/builders/curiosity seekers can follow along. It is not intended to be a detailed description of every step in the building process as that would be much too time consuming. There are plenty of sites that do a great job in that arena, that is not my intention with this site. My intention is for this to be a philisophical/motivational/inspirational account of the emotional ups and downs of the life changing journey...and it will change your life. I hope this will give you an idea, through my eyes, of what its like to make this transformation. A note to other builders, I am not an expert so do not put your safety at risk by attempting anything you see on this site until you have done your own research, or send me an email so we can discuss it. Any deviations from the plans are not approved, nor endorsed by Van's Aircraft or myself. Thanks for visiting.

Monday, February 27, 2012

Last Skins... HOBBS 1157.0 hrs

Still working on the prep work for getting the plexiglass canopy ready for gluing. I may have gotten a little ahead of myself when I made the 'big cut' so quickly, as you can see there was still plenty I needed to do before I can break out the sikaflex and attach my canopy. Oh well, no harm...other than having the canopy taking up room in the shop. I think I'll survive, I'm getting close.

One of the things I wanted to do before I start transitioning into FWF stuff was to better organize my hardware...namely, my AN hardware, this was long overdue. I should have done this sooner but really its been mostly rivets up to this point so it hasn't been too bad. I always have this internal argument with myself, I figure time spent organizing and cleaning is time NOT spent building an airplane. But, I do try to balance it out...some organization is certainly needed. Nothing is more frustrating than spending a half hour trying to find hardware that you have stuffed in a bag somewhere rather than in a nice, labeled parts bin. Since doing this for all of my AN hardware, it has already been so nice to know exactly where to go for the right bolt. Don't be like me, do this sooner rather than later....its worth it.

Builders, over the years, have infamously come to call ProSeal "black death" for obvious reasons and the blue protective plastic on the sheet metal "blue death". Here I am peeling the last of the "blue death" for my project....'THE' very last piece of this devil material! :) It reminded me how far I have come...how many trash cans I have filled with this stuff. I remember doing the wing skins using a water pipe and my forearms were throbbing as I rolled/peeled that stuff off. I'm not going to miss it. This is the second to last top fuse skin...what I thought was my LAST skin on the project, but I realized later that I have one more. The small one in front of the canopy.

Before riveting the skin in place, I wanted to revisit the aft fuse skin to get the three rivets on each side that I couldn't access solo during my first go. I had to remove the seat belt attach brackets to get to the rivets..the bolts were getting in the way of my bucking bar. I then quickly riveted them and re-installed the seat belt attach brackets along with the seat belt cables...and then finalized them to be done with that task. Let me tell you, this was my first odyssey of climbing back into the fuse...holy crap, that sucks! Just getting back there was a challenge. I am not a huge guy...5'9" 185 lbs and I had a hard time...once again, felt like I was doing my 'RV yoga'. I'm hoping there wont be many more reasons to climb in there going forward.

Of course, I had to sign the fuse skin before riveting, like I have done for several of the main skins. Notice I scuffed the surfaces with scotchbrite where I will again add ProSeal to the overlapping joints just like I have for all of my top fuse skins. Water tight, air tight, stronger and vibration resistant...

Last minute fitting and trimming of the rear plexi...I wanted to do as much (or all) of this as I can before riveting the skin. Just a little easier that way.

For the clearance in the corner between the plexi and the attach bracket, I cut a chamfer instead of notching it to fit. I didn't want an inside corner, even radiused, for a possible stress concentration. The skin will cover this so you'll never see it.

Last minute fit check before applying ProSeal and riveting this skin in place. Looking real nice, that canopy is sexy I'm tellin' ya!

Tuesday, February 21, 2012

Scott Taylor Visit HOBBS 1146.5 hrs

Well, it was a busy week for me. First off, I previously mentioned a prospective RV8 builder, Scott Taylor, who joined us at the "Red Tails" movie. Scott is a pilot for Frontier Airlines. He called me up a couple weeks ago and said he had visited the factory, got a demo flight, along with his "first" RV grin. He then promptly took the plunge and ordered his empennage kit! Funny how that works isnt it? Congrats to Scott...welcome to the insanity that is RV building! So, I invited him over to show him my project, the shop and talk tools...of course, 3 hrs later I finally let him leave after talking his ear off. I always seem to do that when it comes to RV's... ;)

Secondly, I took Saturday off from building...first Saturday for quite some time. Of course, it wasn't completely devoid of RV activity however. I went out to FTG and joined Scott Mills for a breakfast flight in his RV9A to Pueblo's Spitfire Grill. It was a nice break from the usual Greeley breakfast run....the rest of the gang went to Centennial. Beautiful day for flying too, it was cold (15 deg F)and the air was as smooth as a babies bottom! Although there was some low lying clouds and haze scattered about...strange for Denver. Believe it or not, it was my first time flying over the clouds as we were at about 1500 AGL coming back from PUB and looking down at the clouds below while basking in bright sun, very bizarre...but gorgeous! I was mad I didn't bring my camera to capture the moment.

Scott let me fly most of the way down to Pueblo, it was nice to get some RV stick time...always good fuel for the fire. After returning, we loitered around the airport for a while...met a new RV7A builder in Chuck's hangar, then we (Gary Zilik, Scott and I) drove over to visit my project and drink a couple beers. It was a great day, a great break from building and great inspiration to forge ahead! Nothing gets me more fired up than a day like that. I suggest you also do this from time to time to recharge.

Finally finished up my rudder pedals as I tidy things up before riveting the forward, upper fuse structure in place in preparation for canopy fitting and glueing. These were overdue on the task list, but with anodizing and painting the powder coated steel tube added some time to the ordeal. I will tell you, and you can tell by the all the pictures, I am very happy with how these came out.

If they had a contest for nicest looking rudder pedals, not sure if I would win because I have seen some nice ones, but I would be in the running that's for sure! :) Too bad you'll hardly ever see them and they will get scuffed up by my feet! Oh well, they look nice now and I'm proud of 'em. The last picture shows my JDAir rudder pedal extensions installed.

Before painting my sub panels with JetFlex satin black, I added a bead of white paintable silicone as part of my "stop the canopy leaks" campaign! Ok, maybe just "minimize" the canopy leaks campaign. ;)

More tying up loose ends in the cockpit...finally getting back to the electric flap install. Here are my after market threaded flap rods that I bought from Avery...and of course, red anodized with the batch of parts I brought in.

Flap motor installed, finalized and don't forget to safety wire it as the Van's AD states....that was kind of a pain. Hooked it up to my portable battery and cycled it up and down a few times to see how she behaved...cooler'n snot!

These support ribs gotta go...they are a bad design, leftover from a time when all panels were 6 pack steam gauges. Nowadays, with flat panel EFIS being the norm, they just get in the way. There are plenty of clever ways to get around this by trimming them or making fancy new ones. As for me, I am just going to cut them off, use the cutoff pieces and strategically relocate them...more on this later.

Finally deciding what to do with my emergency canopy jettison assembly that comes in the kit. I don't plan to have this accessible for an in-flight ejection as I think that is very impractical in reality, but I do want it handy if I ever want to easily remove the canopy on the ground for maintenance.

This is what I came up with...and its been done before, instead of coming through the panel (per the plans) with the T-handle...I just went straight down with it. A 90 degree rotation and off comes the canopy...nice. I need to come up with a way to safety secure this however...don't want it vibrating loose in flight, that would be very bad day!

Support ribs trimmed back as mentioned above...

Don't forget these two -426 rivets...as I almost did...

Jettison assembly and canopy hinge brackets finalized....

Canopy held open for fitting with bailing wire attached to the plywood above...

I made these strut attachment brackets a couple months ago and just realized I screwed them up!! dangit! Read the plans wrong...must've been a late night?? The center holes need to be tapped for the strut ball stud...not through holes as I did. Oh well, add to the scrap pile...how big is yours??! I had enough material left over to redo one...but now I need to purchase some alum bar for the other one.

There is a known problem when installing the tip-up struts. The force of the struts in the closed position exerts enough pressure on the canopy to push is forward slightly and cause alignment problems. I wasnt even aware of this until Sean Blair sent me an email a couple weeks ago...glad he did. So many things to stay on top of, sometimes they slip by.

Clever builders that have gone before me (I seen these on Chad Jensen's site) put "snubbers" in place to combat this. Chad used carriage bolts because the round head is less likely to mar the paint, which I liked. I took it one step further and added vinyl caps that I found at McGuckins hardware store. Of course I had to tweak them slightly to fit and then glued them in place.

The design makes them fully adjustable to fine tune it...but gosh, this would be near impossible to access to adjust once this top skin is riveted in place so get 'em right and hope they dont move. I plan to loctite them.

From the rear side...this is where the vinyl cap will contact the canopy frame.

And a parting shot of the sub-panel finish painted, riveted in place, canopy installed and the rudder pedals partially installed. Wowza, looking good!

Friday, February 17, 2012

Ok, One More! HOBBS 1134.5 hrs

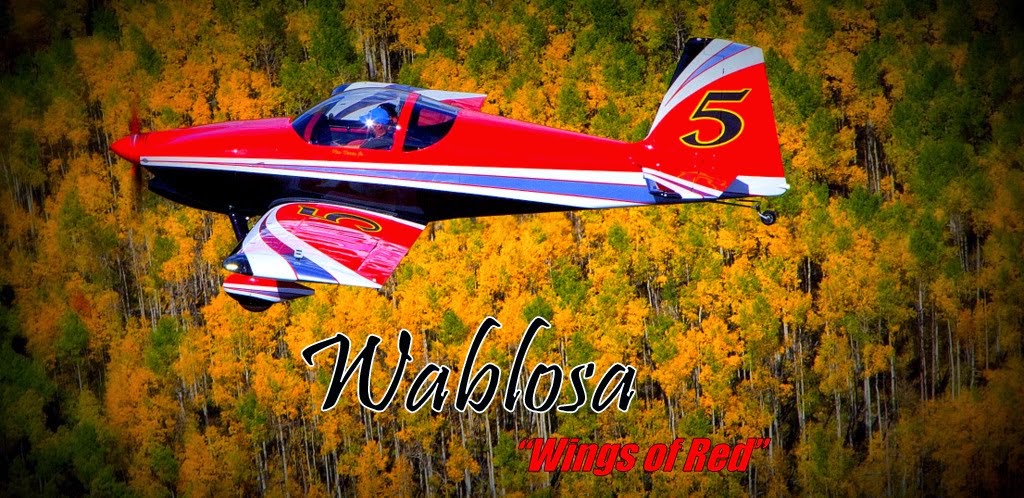

And another good video, of the RV variety this time. Notice the black Crow harnesses (just like mine) and the great visibility of the tip-up canopy configuration. Looks like fun doesnt it? Scenery doesnt suck either. :)

WWII Short Film HOBBS 1134.5 hrs

This is a pretty cool 10 minute short film about WWII fighter pilots called, "The German", that is worth watching. It reminds me of the newly released "Red Tails" movie, but I gotta say the flying scenes in this are actually much better in my opinion. The ending is also very interesting and something I didn't know about WWII history. Very nicely done piece of film.

Enjoy your weekend...I have Monday off for Presidents day, so you know what that means...more time with the mistress! KPR my friends.

Tuesday, February 14, 2012

Canopy Prep Work HOBBS 1131.5 hrs

Just a real quick update to let you know whats been going on in the Factory lately. First off, the hours have decreased slightly now that school is back in session. I have only logged 11 hrs in each of the last two weeks. Down a little from my productive stretch over the break, but this was anticipated as my school workload came back into play.

But have no fear, we are still pressing the attack and on schedule. When I got my finishing kit, as you know, I excitedly jumped right into cutting the canopy. Now that I have that behind me, I realized I have some prep work to do before I can glue my canopy in place with SikaFlex (much more on this later). So, that has been occupying my time in the shop lately.

First order of business was to finish riveting the canopy frame together. As you can see, I haven't riveted the red anodized support brackets yet, that will come after painting.

I was playing around with panel layouts since I need to decide on a strategy so I can modify the mounting ribs behind the panel...the ones that get in the way of any glass panel you install...you'll see what I mean later.

Getting the cross support bracket behind the seats and the gussets finally riveted in place. Dont forget the two -426 rivets.

Roll bar attach brackets bolted in place...ready to receive the roll bar.

Riveted the canopy latch in place and then assembled the mechanism. As you can see I painted this side skin as the CAD interior side panel will have some access holes here and I didn't want bare alum showing.

Riveted my small attach pieces in place as I get these ready to rivet them onto the canopy frame structure.

Not sure if I previously mentioned it, but I bought some Sherwin Williams JetFlex interior paint for the cockpit. This is standard issue, satin black. It took me a handful of batches before I got the mixture right (big, paint learning curve!!) but it is now laying down pretty good. Here you can start to visualize how its going to look in the end.

And another 'to do' item is to finish up my rudder pedal assembly. First task was to paint over the factory 'off white' powder coat. Make sure you scuff up the powder coat good before doing this. I have learned that scuffing (surface prep) is crucial for good paint adhesion...don't skimp on it.

Monday, February 6, 2012

Fiat 500 Commercial HOBBS 1109.5 hrs

Last night I watched the Super Bowl, not so much that I had a rooting interest in either of these East coast teams although I did make a friendly wager with my pop on the Giants just to make things more fun. It was an entertaining game and of course, as you know, the Giants did in fact beat the Patriots to become 2011/12 world champions. The other reason for watching, of course, were the commercials--which are sometimes better than the game.

This particular one for the Fiat 500 made me stop in my tracks with my jaw dropped much like the guy in the commercial...if you seen it, you probably know what I mean. Not just because of the stunning woman, Romanian model Catrinel Menghia, or the fact she didnt speak a word of English in the entire commercial. But it was also the colors that caught my eye...I have, from day one, the utmost confidence my airplane, in a black and red paint scheme is going to be one sexy looking gal--but probably not as sexy as Miss Menghia looked in black and red! ;) wowza, nicely done!

And for some useless trivia...here is the translation of what she had to say...

"What are you looking at?! Are you undressing me with your eyes? Poor guy, you cannot help it? Is your heart beating; is your head spinning...Do you feel lost thinking I could be yours forever?"

Subscribe to:

Posts (Atom)