Now that I am getting back into the groove with building, I can feel the momentum picking back up where I cant wait to get back out in the shop. This weekend, my friend Sean Blair (RV7, Fuse) and his friend, John Armstrong (RV9A, Fuse) drove up from Colorado Springs (60 miles south of Denver) to help me glue the main canopy. They also wanted to get a tutorial on Sika as they both plan to use it on their canopies.

Getting over this hump was huge for me on an emotional level. Not only did it go really smooth, but I was so relieved to have that plexi attached to the frame so it is more sturdy and less likely to crack. I took a big sigh of relief when we finished up and Sean treated John and I to lunch.

In addition, it was so nice to finally have some help (I've done most of this build solo), it was also refreshing to have two more sets of eyes looking at the project. John pointed out something I hadn't realized about my transponder antenna (I'll post on this in a follow up) that I'll need to fix. Its amazing how, you, as the builder don't see obvious things sometimes.

Big thanks to Sean and John...really enjoyed the company and conversation. Sean also brought his full CAD interior package that he just received so I could 'oooo' and 'aaaah' over it. CAD interior is expensive, but they do make a darn nice product, I was very impressed and cant wait to order mine.

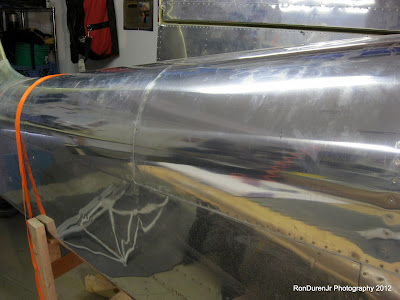

Here is my setup for holding the canopy in place for gluing. Before John and Sean arrived at 9am, I had been working on the setup/prep since 6:30am. I must've put the canopy on and pulled it off 20 times in those couple hours. Checking, double checking, thinking it through, did I forget anything?...masking...etc. Notice the pink foam pad on the side of the canopy...this helps pull the sides of the canopy into the frame nicely when strapped down.

Masking for application of the SikaFlex system. Notice the duct tape to keep the canopy from having too much stress on it while it rests on its back like a turtle. I was nervous with it in this position for obvious reasons. Make sure you have all your edges dressed before even thinking about doing this...even then, be careful.

Another last minute fit check to see how my interior masking lined up...I think we are good to go!

While I had some extra hands in the shop, I wanted to knock out these fuse rivets I couldn't reach solo. Sean ran the gun and I crawled inside the fuse (that's a bitch!) to buck these bad boys. Nice to have that taken care of.

My helpers for the day, introducing Mr. Sean Blair...

...and Mr. John Armstrong. Thanks again guys! I owe ya. :)

Sean was playing photographer while I put on the Sika primer with my foam brush.

A shot of the canopy strapped in place to allow the Sika to dry. I left it this way for about 2 1/2 days before removing the straps. As you can see, I did this while the canopy was in place on the fuse..not on a table. I know the slider guys take it off and do it on a workbench but I wanted to ensure I had the exact alignment to the fuse and the rear canopy. Since I wasn't using any holes in my canopy...not even cleco holes, I figured this was the only way I could pull it off. There were some drawbacks to this since you can't get inside to clean up the excess Sika before it dries, but all in all it worked out well, I liked the fit.

Also, my process for doing Sika was two steps. First step is to do a "structural" bond with the Sika, i.e., don't worry about doing the cosmetic fillets. Second step, later after the first batch has set up good, remove spacers if used, and then do your cosmetics...you know, make it look nice. I had a 65 degree shop in a pretty dry climate and really had no problems with the Sika drying too fast. I might have been able to combine the steps into one...but why put the pressure on yourself. Two steps is a little extra work with extra taping/prep and such but it came out good.

By the way, when doing the second step, I reapplied the Sika activator...I think you technically have a 24 hr window (check the literature) but I just did it to be safe...figured it couldn't hurt.

All in all, Sika, like most of the stuff on this build wasn't nearly as bad as some make it out to be. I think sealing the tanks was worse..ProSeal is nastier to work with than Sika. With Sika, the worst component is the primer. My concerns for structural integrity are non-existent...I did a test piece and was very impressed that not only did the Sika stay flexible, but it was very strong (and this was only about 1 or 2 in^2 piece)...I'm confident this canopy isn't going anywhere in flight.

I was so pumped up after getting the canopy glued in place on Saturday, I was dying to start fairing in the front of the Plexi on Sunday. Here you can see I started using "fine line" tape for make my contour line (1" up from the edge of the plexi)...no bueno! Fine line tape works well if you have a good guide to follow or need to do sharp radii. Otherwise it is just too wavy for my taste, as you can see here. I switched to good ol' electrical tape and it worked much better.

Black dye for my fiberglass layups so you don't see it from the inside of the cockpit...not convinced you need this since I will probably paint the inside of the plexi, but it was only a few bucks at ACS. I also used this bondo spreader for the contour from the sheet metal to the plexi...because its flexible you can control the radius, worked really nice.

First layup...filling the gap with a cotton Flox mixture...since the canopy was still strapped down while the Sika dried, I could only go so far until I remove the straps later. Also note, I didn't add Sika to the front area of the plexi (although I did tape for it)...didn't see a need since the fiberglass fairing will structurally hold this in place and Van's doesnt have screws in this area either.

More filling....I added 1" strips of fiberglass tape over my first layer of Flox that I had left over from my emp tips. I have since ordered 3" and 4" fiberglass tape from ACS, which I will used extensively for the remainder of this fairing work, the side skirts and the targa strip.

And, another layer of Flox to smooth over the 1" strips...its looking good, larger strips and filler will be the last steps before plenty of sanding to make it look pretty.

No comments:

Post a Comment