I distinctly remember when I took the SportAir "RV Assembly" class out in Watsonville, CA, the instructor suggesting that we also take the "Composites" class. Being the neophytes that we all were at the time, we wanted to politely remind the instructor that the RV is an aluminum airframe...not composite, surely he knew that.

His comment was, there is more fiberglass work than you might imagine on an RV. Well, now being a seasoned builder, I can tell you he was right. It is possible to keep it to a minimum, and a lot of builders do because they despise fiberglass work. In the end, you cant get around doing some fiberglass work on the RV's, so you should have some knowledge about how to work with it. I'm glad I took the instructors advice and took the composites class. I enjoy the freedom of expression and craftsmanship that fiberglass work allows, but the sanding...you can keep it! ;) Dirty, nasty work--it certainly makes you feel fortunate to be building an aluminum aircraft.

So, this weekend I got elbows deep into fiberglass work on my canopy. From my glass work on the empennage, although I am still no expert, I feel pretty comfortable with the process now. Lots and lots of layups during the week and then again on Saturday...then trimming, cutting, sanding on Sunday. Here are some pics...

First of all, I needed supplies to get started...I already had my West Systems epoxy from the emp, but now I needed to procure some 3" and 4" fiberglass tape from Aircraft Spruce.

I was introduced to the of "Perma-Grit" line of products in my composites class. A little pricy ($30) for this sanding block, but they work great and supposedly last forever. As I always say, get the right tool for the job...work smarter, not harder.

And the enigma that I am...I spend $30 on a fancy sanding block, but use hair spray for a poor man's "mold release"! :) Mold release is expensive...hair spray will work just fine for what I am doing, although try to find unscented if you can...I'm already tired of the shop smelling like an old lady at church. ;)

Lay out some good ol' fashioned saran wrap on the work bench for doing layups...I cut my strips to size and then apply my resin on here...doesn't stick, works great...another tip from class.

Deviating from the plans...again...I am doing fiberglass side skirts, rather than riveting on the alum that Van's specifies. This will look much nicer and blend into my "targa" strip much cleaner.

Doing a few more layups with the 3" tape on the front fairing. Structurally this is about done, fill work should be all that's left now to make it look pretty.

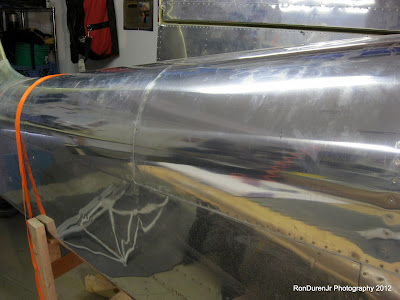

And now I start on my 'targa' strip over the top of the roll bar. Overlap the corners, alternating back and forth. Let me add, before I did these layups I put plenty of tape (duct and masking) in all areas I didn't want the fiberglass to adhere to. The last tape layer was clear packing tape since nothing sticks to that stuff, and finally my hair spray...er, mold release...sprayed onto those areas. You do the layup...let it set up good and then go back and pop the canopy loose if all goes well.

I was worried about gluing my canopy shut, and rightfully so, consequently I didn't do it all at once...side skirt first, then most of the targa strip, and lastly the other side skirt and remainder of the targa strip. Three separate steps. Each time, it was a little nerve wracking trying to carefully pop the canopy loose.

Here is a shot of what my targa strip is looking like when the canopy is open...

"Feather" the layers of fiberglass up to the edge so you don't have a big ridge at the transition from plexi to fiberglass.

And again...deviating from the plans...I don't really like the small little handle that Van's has in the plans to open the canopy. I always felt like it was so small it was going to slip out of my fingers. So I purchased a piece of alum extrusion at McGuckins and fabricated this little guy, with a return flange for a good finger hold.

I pop riveted this into place since it would've been difficult to solid rivet it...

...and then glassed in around it to cover the rivets...she's not going anywhere now and will look nice and clean. I like how this turned out...

I know you've seen this before...but I still get a kick out of watching my canopy open and close! ;) Fits like a glove already! You can see how the targa strip overlaps for a good tight wind and water seal...far superior to leaving that joint exposed, in my humble opinion. But remember...although the targa strip is superior in functionionality, it does add weight so make the call on your airplane whether you think its worth it. Its always a tradeoff...just make your decisions to deviate with your eyes wide open.

Ok, so now that I am done with the initial layups...I pop the canopy loose for the last time and remove it for trimming. As you notice, my glass worked was intentionally bigger than what I needed. Now I trim it to size with a cutting wheel in the die grinder. And of course, the fiberglass dust begins...ugh, it gets everywhere.

I am trying something that I haven't seen anyone do (although I'm sure I'm not the first). I am overlapping the side skirt to have a nice seal..again for wind and rain. The plans say to bring the side skirt down to the edge of the fuselage skin and leave that gap as is. I did some research to see if anyone has tried this and I found an old post in the archives where someone had asked Van's about doing this and their response was "it cant be done since it will rub the paint off." Well, I don't like to be told "it cant be done"...its my rebellious side I guess...so I'm going to try this, we'll see how this comes out, see if I'm successful. So far, its looking real good and I don't see any reasons why this can't, and won't be successful. I have a couple ideas about the paint rub problem too.

Trimming the targa strip....

The long sanding process underway...notice the white, fine, dust...everywhere...my poor shop, and me!

Cutting the corner radii for a nice, finished look...its starting to take shape, exciting stuff.